The road of the future is here.

Stronger. Faster. Greener. Cheaper.

Rombus Surfaces.

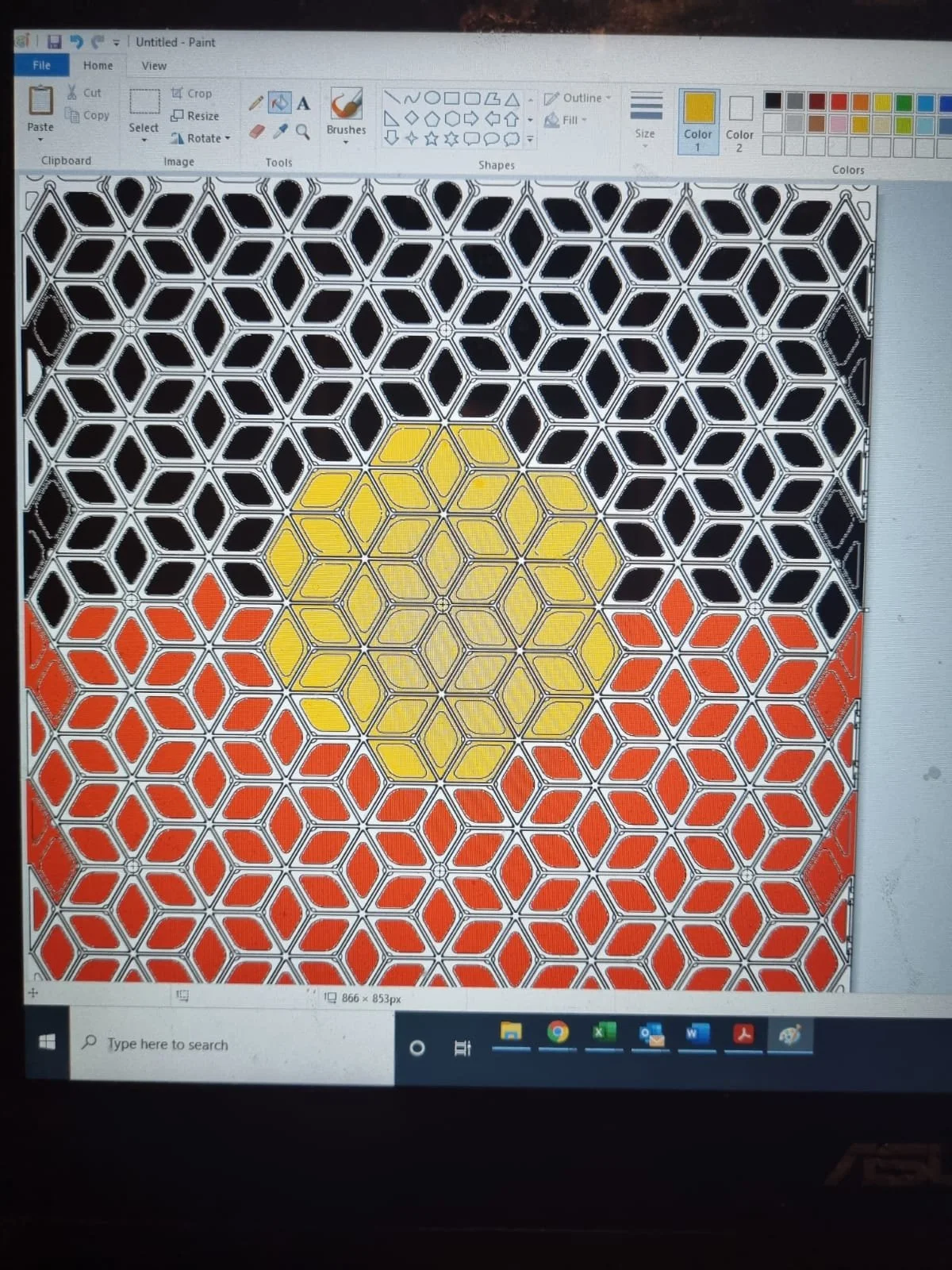

The Rombus flexible surface solution is a dust-free, gravel-free wearing course

that serves the same function as asphalt or concrete slabs, only with superior wearing and strength properties.

It is the first flexible pavement system with a hard concrete surface.

Installation is an easy 3 stage process consisting of ground preparation, grid install and fill, then finish with Rombus approved mix design and desired finish.

-

Commercial

Need an unbreakable road or factory floor?

-

Agricultural

Fast, simple and efficient hard stands ideal for shed floors, wash bays, stockyards, feedlots, and driveways. Let us fix those farm headaches.

-

Residential

Get it done once. Tricky terrain no problem.

-

Retail

Need a floor as strong as it is aesthetic?

the future of surfacing is here

problems we solve:

-

poor drainage

Whether it be a suburban path or remote feedlot, poor drainage and erosion can cause expensive headaches such access issues, hardstand collapse and surface failures. Rombus can be filled with permeable fill to avoid these issues and their associated expense.

-

dust management

Uncontrolled dust also contributes to challenging and expensive health and equipment maintenance problems.

-

cost saving

Particularly when jobs are regional or remote, costs can blow out if not completed efficiently. Rombus is modular, making for much faster installation times and reduced construction schedules.

Less concrete and no formwork or steel ties are a cost-saver, and because concrete trucks can drive onto the empty grid, the significant cost of a concrete pump can be avoided. -

failing pavements

An all-too-common occurence that can easily be prevented using Rombus. Not only are pavement fractures are hazardous and can interrupt business and access.

-

safer work

The Rombus grid weighs 5.4 kg per 1m2 sheet, saving employees the heavy and awkward task of working with steel mesh. There is also less concrete to move around. Both of these things make work easier and safer.

WHY IT MATTERS

Roads and pavements form a large part of the urban environment. Cement is responsible for 6-8% of the worlds carbon emissions.

Replacing traditional concrete slabs and pavements with Rombus hybrid

pavement system can reduce your carbon footprint by up to 90%.

Reducing concrete in these will lower carbon emissions, conserve resources, improve air quality

and lower construction costs.

In some applications, you may want to do away with concrete altogether!

Rombus is a less dense structure drawing and releasing heat into the atmosphere.

In this way, Rombus can keep suburbs cooler.

We need to reduce the amount of concrete we use. Rombus is one significant way to do that.

NERD THINGS:

Where normal highway vehicles including trucks are to be accommodated, the Austroads Guide to Pavement Technology Part 2: Structural Design Section 8.3 is to be applied.

Where heavy duty loads such as forklifts, reach stackers, mine haul vehicles or any non-standard vehicle with wheel loads over that of highway trucks are operated, design shall be undertaken using:

i) the Barker-Brabstone method of sub layering

ii) Leigh Wardle, Ian Rickards, John Lancaster and Susan Tighe (2007) Heavy Duty Industrial Pavement Design Guide, Mincad Systems, Melbourne (HiPave design software (uses Barker-Brabstone method))

iii) Roger Thompson, Rodrigo Peroni, Alex T. Visser (2019) Mining Haul Roads Theory and Practice, CRC Press

In airport surfaces, any CASA approved methods may be applied. The product would be suitable for taxiways and aprons, however consideration is required for the application in the touchdown areas of runways where further analysis will be required. In any airport runway application, either flexible or bound, design shall be undertaken in accordance with Civil Aviation Safety Authority (2011) Advisory Circular Strength Rating of Aerodrome Pavements.